copyright© 2014 Piscinadimare.it S.a.s.

Carbon Dioxide for Swimming pools

A precise control of pH value is a necessary element in the disinfection of swimming pools and spa water, as it maximizes the redox potential for oxidation of organic matter. Precise pH balance, within a proper ranges, will maximize the life of the pool structures and surfaces and the components of the recirculation systems. Our Carbon Dioxide Feed System would eliminate the hazards and the hassles of handling acid-based products. Muriatic acid is dangerously corrosive; handling this chemical is very dangerous to the untrained.

A study published in the scientific journal Chemosphere in 2010 suggested some further advantages of using CO2. It found that its use slightly reduces the carbon footprint of a swimming pool, producing less greenhouse gas. It also found that three pools that changed from hydrochloric acid to CO2 had lower chlorine consumption, lower levels of oxidants in the air above the swimming pool and of trihalomethanes in the pool water. Further research is needed to determine if the buffer effect of CO2 is the main factor in this.

Carbon Dioxide is a non-flammable gas. When mixed in water, it forms a very mild acid (Carbonic Acid), which is strong enough to maintain pool water within the appropriate pH range (7.2-7.8), without damaging your equipment. Since your facility already has a bulk CO2 tank in place, you can now benefit from this chemical in your pool, with minimal handling of CO2 cylinders.

How it Works

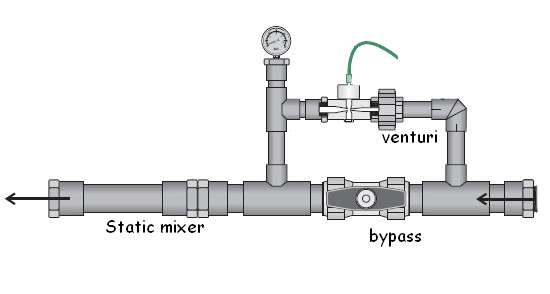

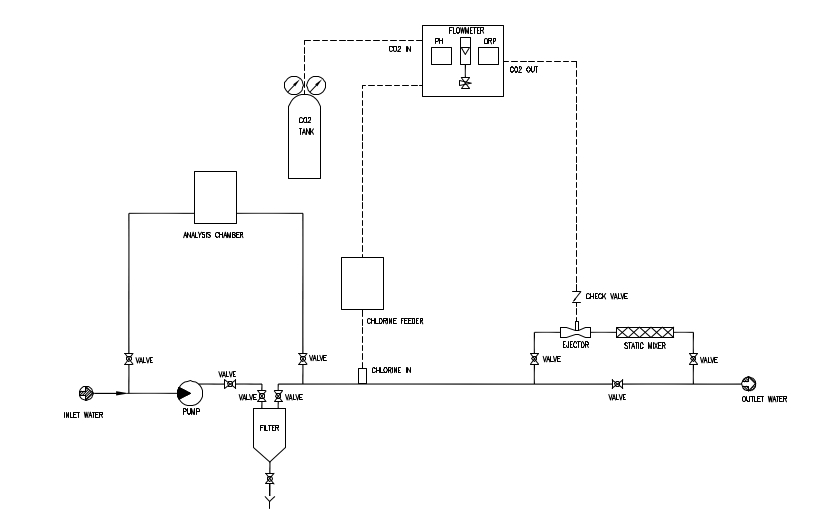

The ECO 2 control unit operates at a low pressure (2 bars) and come complete with a feed supply adjustable regulator and gauges. Mount the system securely to a standard high pressure Carbon Dioxide cylinder. PVC injector check valve chamber should be plumbed into the return line in appropriate location as determined by installer and connected to the system with 3/8" flexible tubing included. The high pressure CO2 cylinders can be filled at any welding shop or microbrewery. Operation and Maintenance The flow rate has been preset to meet maximum demand for CO2 pH control. The controller shall actuate the flow control solenoid valve to provide pH correction as determined by our factory preset proportional feed control logic. Maintenance of the flow control unit is minimal, normal care in cleaning is advised. Field information and research indicates that it is impossible to achieve a pH value below 6.7.

|

ECO2

(Carbon Dioxide)

|

Solforic & chloridric Acid

(pH- liquid or powder)

|